Something went wrong... Please try again.

KI-10 Facade fixing with plastic pin

Hammerset insulation fixing with reinforced plastic nail

Features and benefits

- Installation in all substrates (categories A,B,C,D,E).

- The plastic nail reduces heat transmission (value 0.0W/K)

- Plastic nail reinforced with glass fibre allows fast and trouble-free installation with correct expansion of the plug.

- Expansion zone designed for low embedment depths, reducing the amount of drilling required.

- Can be used with additional KWL insulation holding plate, available in 90, 110 and 140mm flange sizes (recommended for soft insulation materials such as mineral wool).

- Optimal product parameters enable cost-saving solutions.

- Optimum plate stiffness ensures stability and excellent pull-over values

Product information

Size |

Product Code |

Fixing |

Fixture |

||||

Diameter |

Length |

Plate diameter |

Recommended thickness |

||||

d |

L |

D |

tfix A, B, C |

tfix D |

tfix E |

||

[mm] | |||||||

Ø10 |

R-KI-070 |

10 |

70 |

60 |

35 |

20 |

0 |

R-KI-090 |

10 |

90 |

60 |

55 |

40 |

20 |

|

R-KI-120 |

10 |

120 |

60 |

85 |

70 |

50 |

|

R-KI-140 |

10 |

140 |

60 |

105 |

90 |

70 |

|

R-KI-160 |

10 |

160 |

60 |

125 |

110 |

90 |

|

R-KI-180 |

10 |

180 |

60 |

145 |

130 |

110 |

|

R-KI-200 |

10 |

200 |

60 |

165 |

150 |

130 |

|

R-KI-220 |

10 |

220 |

60 |

185 |

170 |

150 |

|

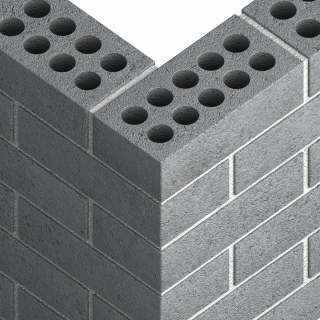

Base material

-

Concrete C12/15-C50/60 (Use category A)

-

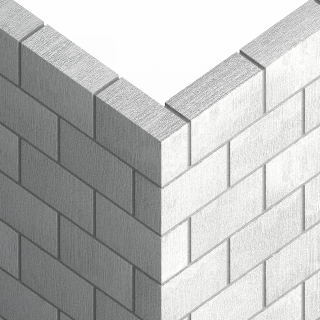

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

Hollow Sand-lime Brick (Use category C)

-

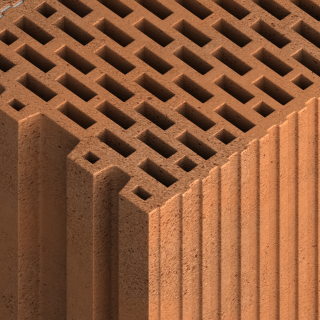

Vertically-perforated clay block (Use category C)

-

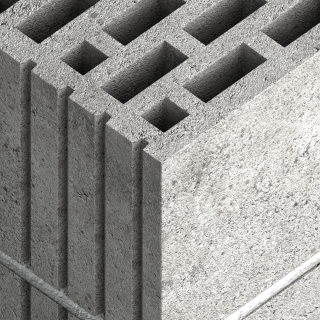

Hollow Lightweight Concrete Block (Use category D)

-

Lightweight Concrete Block (Use category C)

-

.png)

Reinforced components of lightweight aggregate concrete (Use category D)

-

Aerated Concrete Block (Use category D)

Applications

- External Thermal Insulation Composite Systems (ETICS)

- Polystyrene boards

- Mineral wool (MW) boards

- Light wood wool building boards

- Polyurethane boards

- Wood fibre boards

- Lightweight recycled panels

- External Thermal Insulation Composite Systems (ETICS)

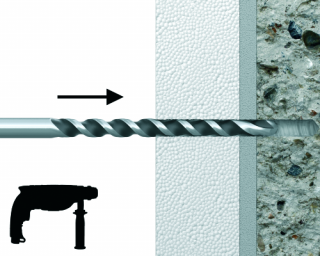

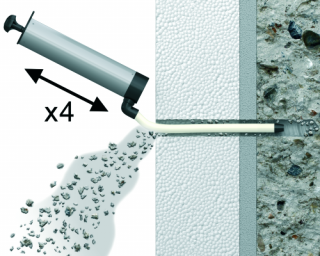

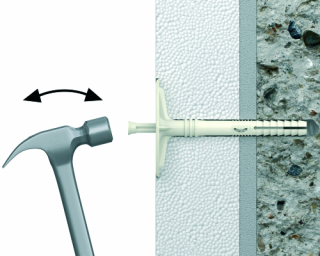

Installation guide

- Drill a hole of required diameter and depth

- Drilling depth of min 35 in masonry, 50mm in perforated materials and 70mm in lightweight concrete block and aerated concrete

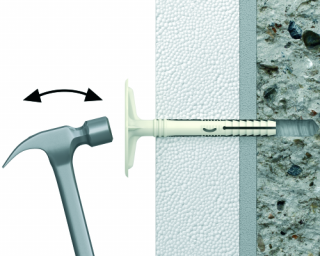

- Lightly tap the plastic sleeve through the insulation material into hole with a hammer, until fixing depth is reached

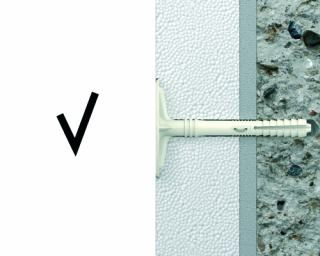

- Embedment depth of min 25 in masonry, 40mm in perforated materials and 60mm in lightweight concrete block and aerated concrete

- Lightly tap the plastic nail into the plastic sleeve until fixing is secure and flush with insulation material.

Installation data

Substrate |

A, B, C |

D |

E |

||

Hole diameter in substrate |

d0 |

[mm] |

10 |

10 |

10 |

Min. hole depth in substrate |

h0 |

[mm] |

35 |

50 |

70 |

Min. installation depth |

hnom |

[mm] |

25 |

40 |

60 |

Min. substrate thickness |

hmin |

[mm] |

100 |

100 |

100 |

Min. spacing |

smin |

[mm] |

100 |

100 |

100 |

Min. edge distance |

cmin |

[mm] |

100 |

100 |

100 |

Fixing diameter |

d |

[mm] |

10 |

10 |

10 |

Downloads

- KI-10 Facade fixing with plastic pin - Technical Data Sheet

- 1488-CPR-0368-Z_EN.pdf_1.pdf

- ETA-07_0291_KI-10_KI10M_EN.pdf

- UKTA_KI-10_0836-22_6369_2022_EN.pdf

Need documents for other product? Visit our Technical Library.

go to libraryContact us to get information about product availability and its price