Something went wrong... Please try again.

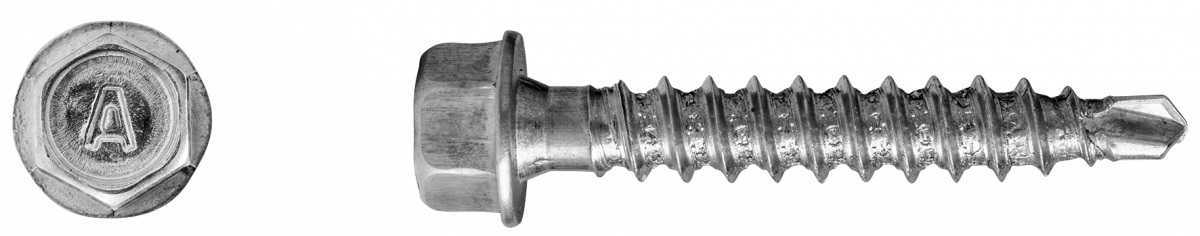

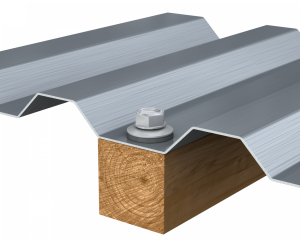

ODA Aluminum self-drilling screws for timber

Special design of the drill point guaranteeing quick and firm installation in wooden substrate

Features and benefits

- Coloured polyester protective coating with a thickness of 45-50 um (RAL, NCS, RR), provides additional protection against corrosion. Various colours available to suit all metal sheet variants. UV stabilizers ensure colour quality over a long period of use.

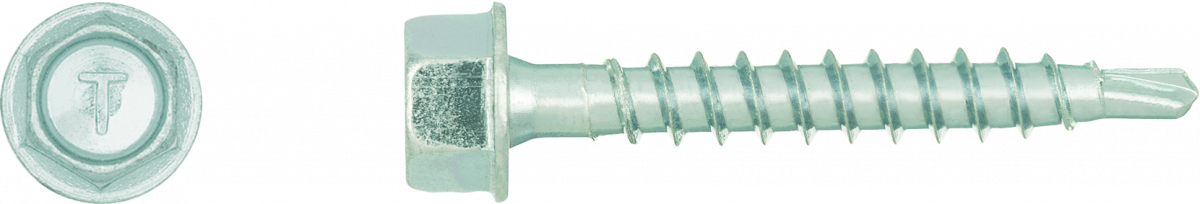

- Hardened surface of the thread (flexible core). Shape and type of thread designed specifically for use in wood construction.

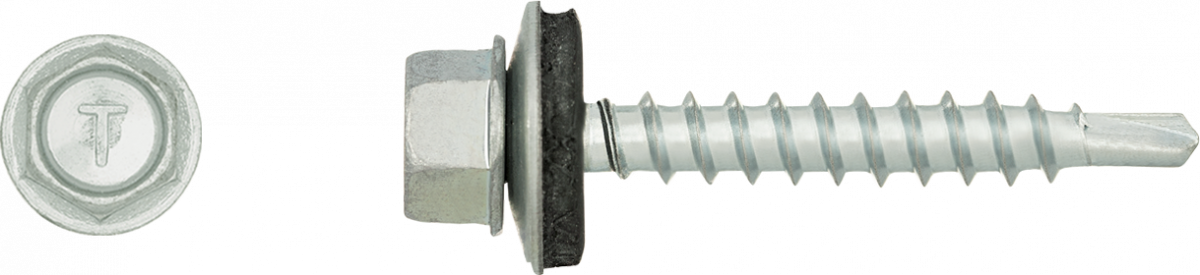

- Self vulcanizing EPDM washer. Temperature and UV resistant. The special shape of the washer ensures proper seating of the sealing material on the outer cladding material fixture which guarantees a proper seal.

- The drill point is designed to provide a fast and hassle-free installation in wood. Sharp point of the drill prevents movement of the surface of the fixture.

- Reduced drilling point ensures optimal tightness and correct hole diameter in the wood.

Product information

Size |

Product Code |

Screw |

Fixture |

Washer size |

Max. drilling thickness |

RAL Colour |

||

Diameter |

Length |

Head size |

Max. thickness with washer |

|||||

d |

L |

S |

tfix |

- |

- |

- |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

- |

||

Ø5.5 |

ODA-55035A |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

- |

ODA-55035A3011 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

3011 |

|

ODA-55035A5008 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

5008 |

|

ODA-55035A6020 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

6020 |

|

ODA-55035A7016 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

7016 |

|

ODA-55035A7024 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

7024 |

|

ODA-55035A8004 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

8004 |

|

ODA-55035A8017 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

8017 |

|

ODA-55035A9005 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

9005 |

|

ODA-55035A9010 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

9010 |

|

ODA-55035A9999 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

9999 |

|

ODA-55035ARR750 |

5.5 |

35 |

8 |

1.5 |

14 |

2.5 |

- |

|

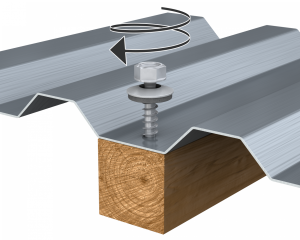

Base material

-

Timber

Applications

- For fixing of: Profiled sheet to wood

Installation guide

- Screw must be installed at 90 degrees to substrate.

- Magnetic driver must be used.

- Lowest torque setting on impact screwdriver to start.

- Reduce speed when the washer starts to deform.

- Use a cordless Impact screwdriver. Note: Never use a power drill.

- For installation please use screwdriver of load capacity 1600 - 2000 rpm with regulated trogue.

Installation data

Size |

Ø5.5 |

||

Hole diameter in substrate |

d0 |

[mm] |

- |

Min. hole depth in substrate |

h0 |

[mm] |

- |

Min. installation depth |

hnom |

[mm] |

30 |

Min. substrate thickness |

hmin |

[mm] |

30 |

Min. spacing |

smin |

[mm] |

30 |

Min. edge distance |

cmin |

[mm] |

25 |

Wrench size |

Sw |

8 |

|

Screw diameter |

d |

[mm] |

5.5 |

Contact us to get information about product availability and its price